Quality that stands the test of time

Every Prismo® product is shaped by precision, from how it’s formulated to how it performs on the ground. Behind every line, joint, and stud is a process refined over decades, built to deliver consistency, durability, and confidence.

Engineered to perform

Our manufacturing sites are equipped with cutting-edge machinery and run to exacting standards, but it’s the deep experience of our team that ensures every product is road-ready. Whether for highways, runways, or bridges, everything we make is engineered for safety, usability, and the real world.

Industry leading performance

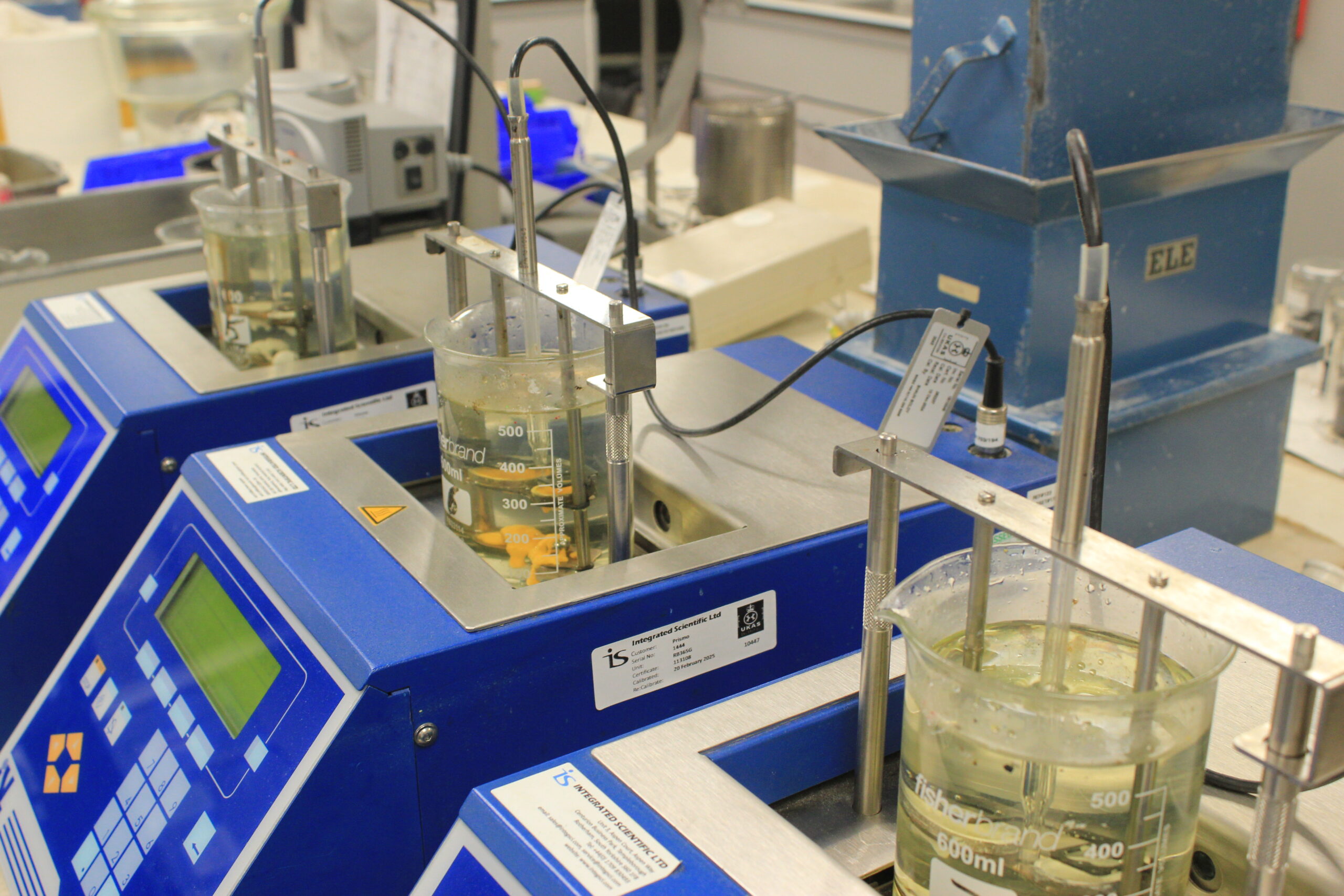

We pride ourselves on delivering performance you can count on. At every stage of production, our teams bring practical knowledge and technical precision so each product performs as specified. Every batch is checked and signed off before it leaves the line.

Verified in real conditions

Quality control covers formulation, adhesion, reflectivity, skid resistance and colour. Improvements are proven in the lab and verified on real surfaces in real conditions. From the way our thermoplastics bond to the road to the clarity of our paints in harsh weather, everything is built for lasting performance.

Built to outperform

Our manufacturing standards go beyond compliance. They’re built to deliver lasting value across every environment we serve. Every feature is engineered for one purpose: reliable, long-term performance where it matters most.

Engineered for climate extremes

From alpine roads to desert heat, our products are proven in demanding environments.

High-performance formulations

Adhesion, visibility and wear life are optimised across the board.

Consistent quality control

Every batch is tested to perform. We’re exacting because performance matters.

Designed with longevity in mind

Fewer replacements. Fewer delays. Markings that keep people moving safely.

Inside our UK manufacturing facility

Our state-of-the-art thermoplastics facility in Chorley is the largest of its kind in Europe. It’s precision-built for scale, accuracy, repeatability, and innovation.

Making better choices

Sustainability at Prismo starts long before our products reach the road. Our UK manufacturing facility runs on 100% renewable electricity. Across all sites including Italy and South Africa, we’re focused on reducing energy use, cutting waste, and lowering emissions.

Recycled content

We already use 91% bio-based resin in our thermoplastics, with a goal to reach 100% within two years. Up to 45% of the material is recycled content and we’re actively developing new formulations that increase recycled content without compromising performance. Waste is repurposed into new formulations, and our R&D teams are constantly working on solutions that combine performance with environmental care.

Durable products reduce replacements. That’s better for customers, and the planet.

Global scale. Local focus. Total precision.

Our manufacturing plant in Chorley is a core part of a wider network that includes two manufacturing sites in Italy and one in Johannesburg, South Africa. This means that wherever your project is based, our sites work as one to guarantee consistency, reliability and lasting results.

Global expertiseExplore how we support you.

Send us a message

Ready to find out how our manufacturing expertise can support your next project? Our team is here to help.

Prefer to speak to someone local?

Get in touch with your regional expert for tailored advice and detailed product information.