Shaping the future of road marking

Innovation at Prismo® starts with what contractors, specifiers and local authorities need. Clearer markings. Fewer failures. Materials that hold up in rain, heat or high-traffic wear. Our R&D responds to what happens on real roads. This is road marking innovation grounded in practice, so products perform first time and keep delivering.

Solutions that changed how roads are marked

Since 1935, we’ve delivered systems that changed the way roads are marked. Each one has improved visibility, durability, and safety for road users around the world.

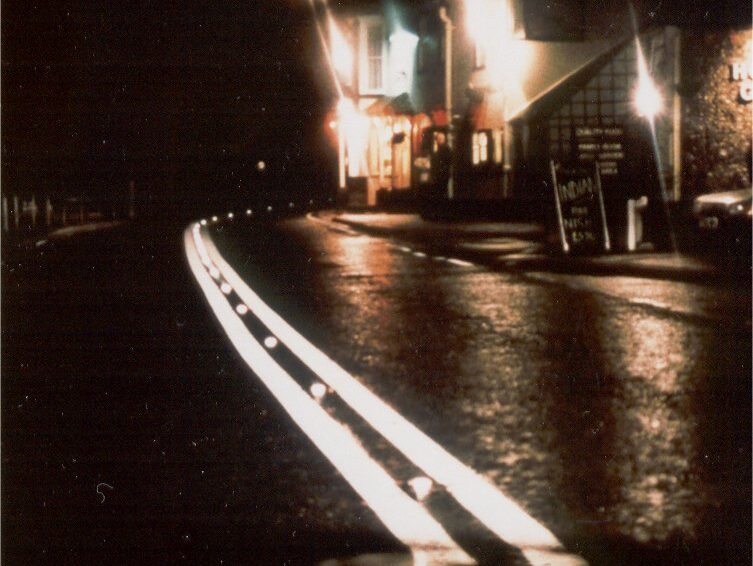

Reflective road markings (1938)

We were the first to introduce reflective glass beads in road markings, dramatically improving night visibility and driver safety.

Thormajoint® (1970s)

The original asphaltic plug joint system for bridges, Thormajoint® delivers flexible, lasting protection for bridge expansion joints. It remains the standard worldwide.

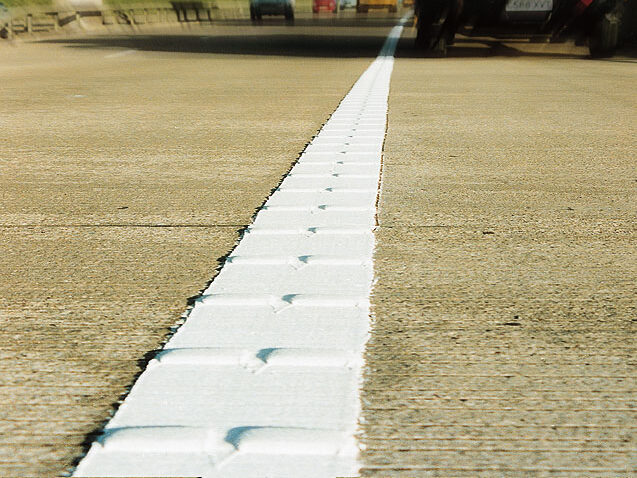

Sprayplastic® (1980s)

We developed the first spray-applied thermoplastic marking, speeding up installation and minimising traffic disruption.

Vibraline® (1980s)

Prismo® created the initial profiled thermoplastic rumble lines, providing audible and tactile alerts to drivers straying off course, helping to reduce accidents.

Rainline® (1990s)

Rainline® was the industry’s first road marking designed specifically for wet conditions. Its unique profile maintains clear visibility even in heavy rain.

Moisture-proof thermoplastic (2000s)

Our moisture-tolerant thermoplastic adheres to damp surfaces. This innovation allows faster marking after wet weather, reducing delays.

Applied research

Cutting-edge R&D

Our advanced research and development facilities in Chorley play a vital role in keeping us at the leading edge of the industry. This is where new ideas are tested, refined, and proven before they reach the road.

In our specialist lab, the technical and quality teams put every product through its paces. We test for reflectivity, skid resistance, durability and colour retention. These checks ensure every system performs reliably where it matters most.

Each product begins with a specific challenge in mind. Some are created to reduce traffic disruption. Others are developed to lower environmental impact or improve visibility on worn surfaces. Every solution is designed to achieve a measurable outcome.

We also work closely with suppliers, contractors, and specifiers to understand what’s changing on site. That collaboration shapes the next generation of road marking systems.

Meeting today’s challenges

-

Eco-friendly formulations

We’re reducing VOC emissions and exploring bio-based alternatives, without compromising performance.

-

Heat-resistant thermoplastics

Engineered for high temperatures, helping markings stay visible and stable in hotter climates.

-

Rapid-dry paints

Designed for cold or changeable weather, these systems speed up application and reduce downtime.

-

Simpler, safer application methods

We’re improving how products are installed, making it safer for crews and faster for road users.

The longer a marking lasts, the less time crews spend going back to it. Our goal is always to cut maintenance cycles and help things run more smoothly. Better-performing materials keep roads open, budgets on track, and users safe.Get in touch

Development runs through everything we do

Every part of the company contributes to product development. From material sourcing and testing to manufacturing and on-site application, each stage feeds back into how we improve. If a material doesn’t perform where it’s needed, it doesn’t make it into our range. That’s the standard we hold ourselves to.

Discover our latest thermoplastic innovationsSee how innovation drives everything we do

Need technical advice?

Have a spec to discuss? Want to improve performance on site? Our technical and development teams are ready to help from first question to final install.